*NOTE: This blog post is out of date. Some information may no longer be relevant.*

“Dust in the wind” may be a great poetic analogy for a melancholy 80’s rock song, but in reality we generally don’t like dust.

Large particles are filtered in the upper respiratory system, but the smaller the particle, the farther into the airways they penetrate.

Dust particles are measured in micrometers (μm or um), also know as microns. Particles that are 10 microns and larger are typically not detrimental to health. These would include dust, pollen, and mold spores. Of course, some materials can be dangerous regardless of size, but other particulates are dangerous because of their size.

Particulates that are in the 2.5 micron range can penetrate deeply into the lungs. This classification of particle size is generally called PM2.5 and includes particles that are approximately 2.5 um and smaller. These smaller particles can reduce lung functionality and can lead to significant health effects, especially for those with already-compromised cardiovascular systems.

The actual chemical composition of these particles can differ dramatically in different environments. In some cases, particulates may consist of silicates (sand dust) and in other environments it may be ammonium nitrate.

In the mountain valleys of northern Utah, where Dyacon is located, pollutants can become concentrated during winter months. This leads to changes in air chemistry that cause the formation of particulates. You can read more about this on the FAQ page prepared by the University of Utah Department of Atmospheric Sciences.

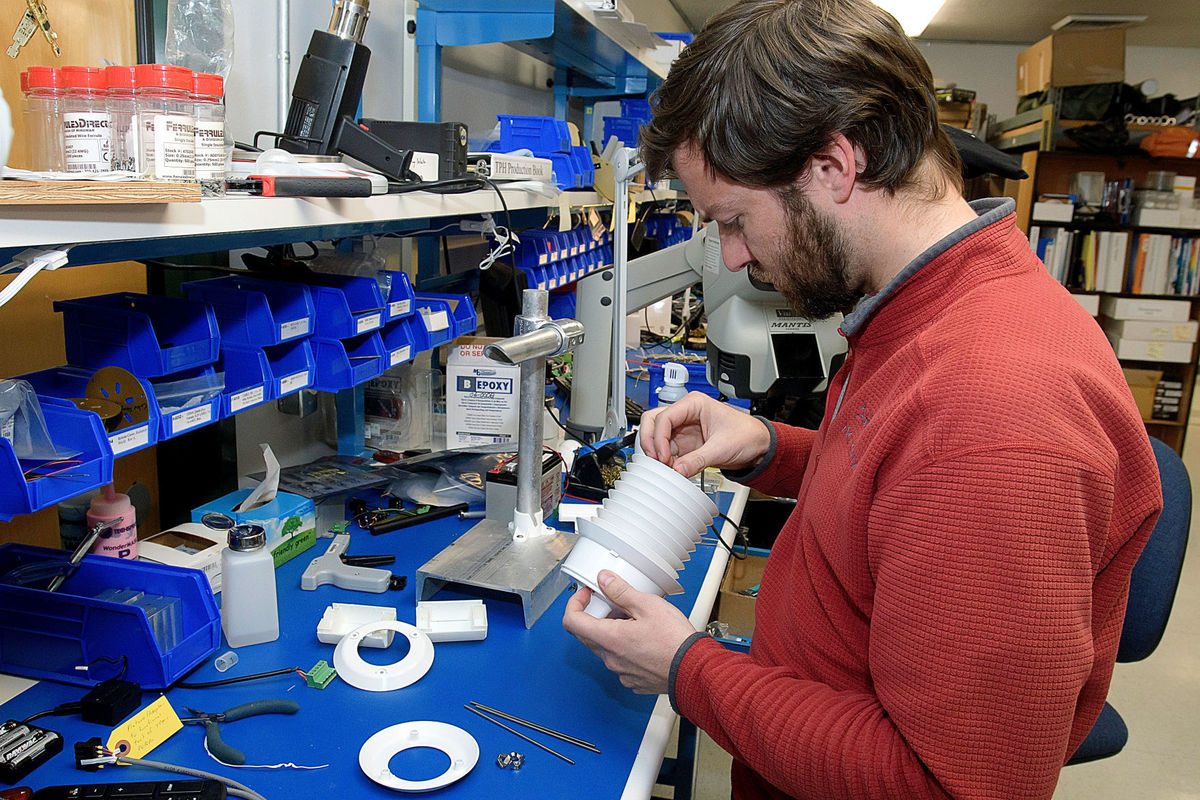

Dyacon PM Sensor

In our mission to build useful, practical equipment for commercial and industrial applications, we have begun the development of a PM sensor. We have several prototypes in the field and expect to release a solution in Q3 2018.

Like other Dyacon sensors PM-1 (tentative name) is a Modbus RTU sensor that is compatible with existing Dyacon weather stations. Using this standard industrial protocol also means that it can connect directly to industrial automation controllers, building automation systems, and other compatible master devices.

As we continue our development of this product, we would be interested in any input you may have for your application. This would help us develop calibration profiles that would be suitable and valuable for your specific environment.

Eugene

(Oh, we did get a little write-up in our local news paper, The Herald Journal.)