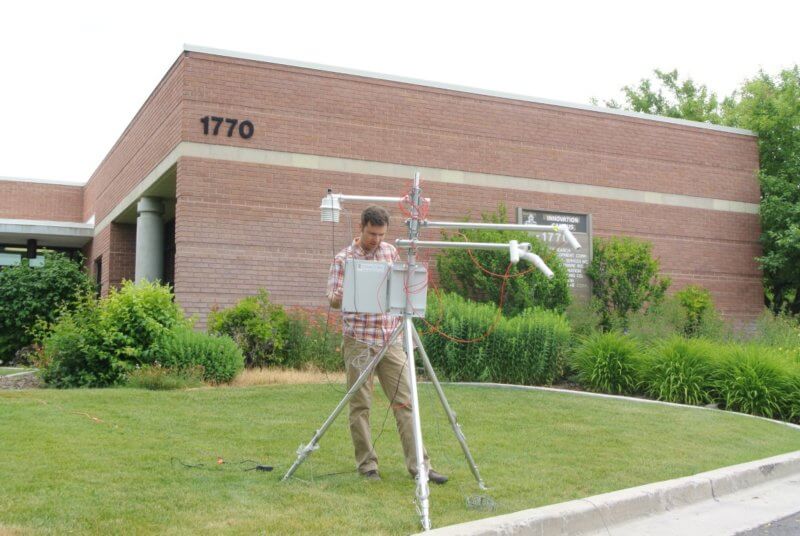

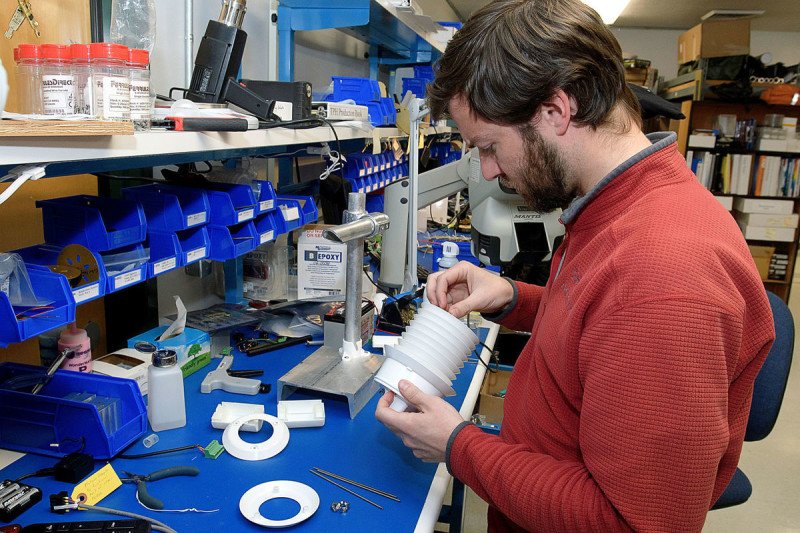

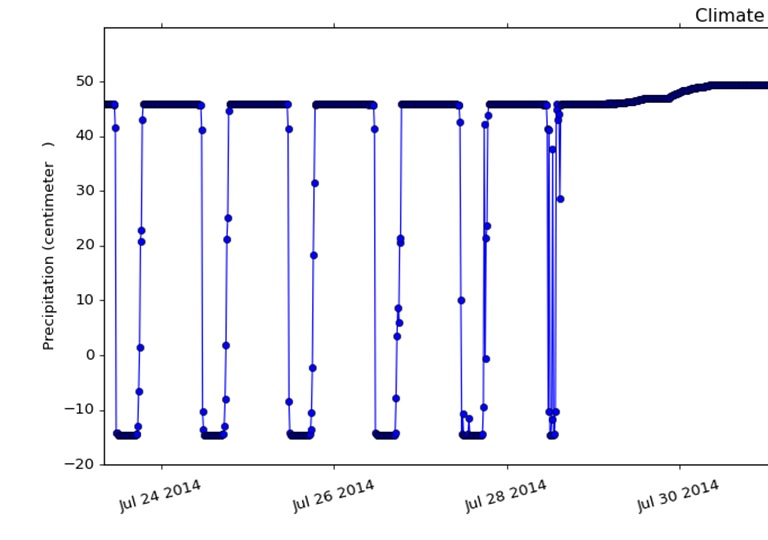

There is a reason we don't make plastic anemometers. The following was emailed to me by Zach, who operates a Dyacon weather station network in Nebraska for the Vantage Agri…

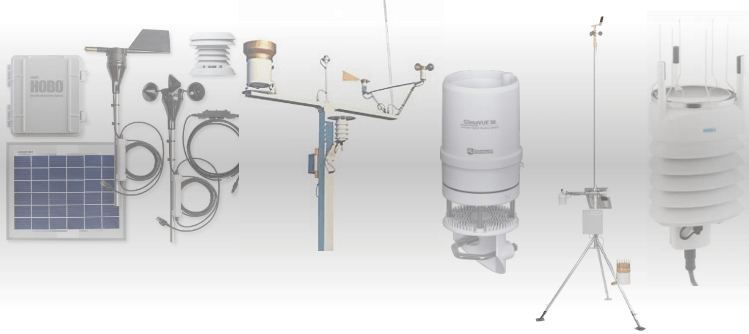

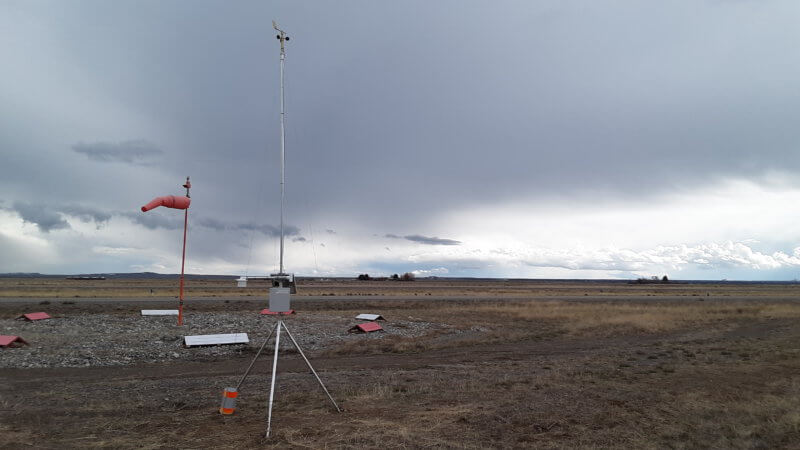

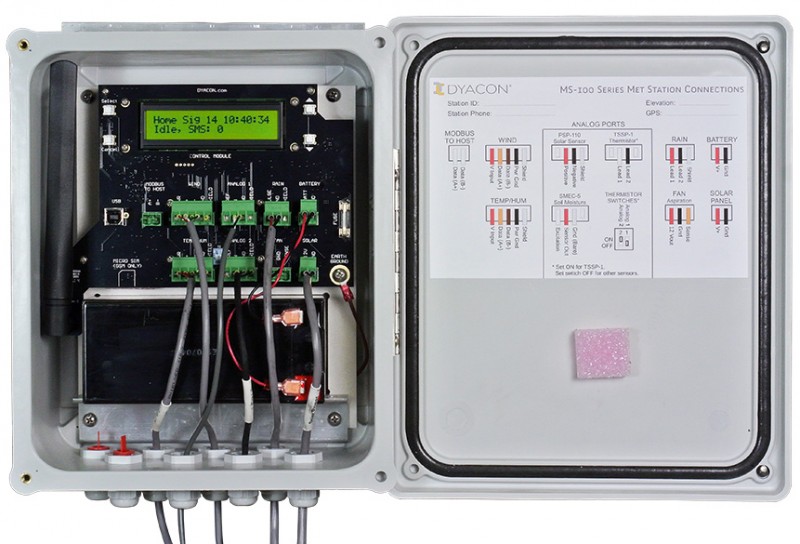

Read More This article is part of a series entitled “Introduction to Industrial Weather Stations” (IIWS). The other parts are: Part 1 – Definitions Part 2 – Weather Station Construction Part 3 – Who Makes…

Read More This article is part of a series entitled “Introduction to Industrial Weather Stations” (IIWS). The other parts are: Part 1 – Definitions Part 2 – Weather Station Construction Part 3 – Who Makes…

Read More