Description

Video

Description

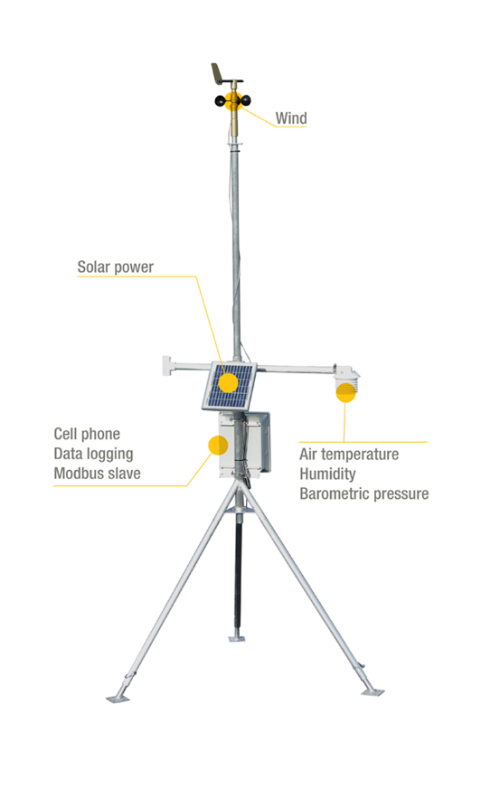

RGTB-525i™ is a practical, high-value tipping bucket rain gauge with a 6 inch (15 cm) orifice. RTBT-525U™ is the 8 inch (20 cm) variant. These two rain gauges are made in the US by Texas Electronics and balance performance with compact size and ruggedness. Dyacon adds it’s own versatile mounting bracket that can be used for mounting the rain gauges directly to any pipe, post, or flat surface, including directly onto the Dyacon tripod.

Like other tipping bucket rain gauges, RGTB-525’s use a high-reliability reed switch, that closes momentarily with each tip.

Feature Summary

- 6” (152 mm) orifice or 8″ (20.32 mm) orifice

- Tipping bucket mechanism

- Large debris screen

- Easy to service

- Reed switch tip detection

- Integrated bullseye level

- Versatile Dyacon mounting system

- Powder-coated aluminum body

- Made in US

Key Features

Exterior Construction

Powder-coated aluminum.

Top is easily removable for installation and maintenance

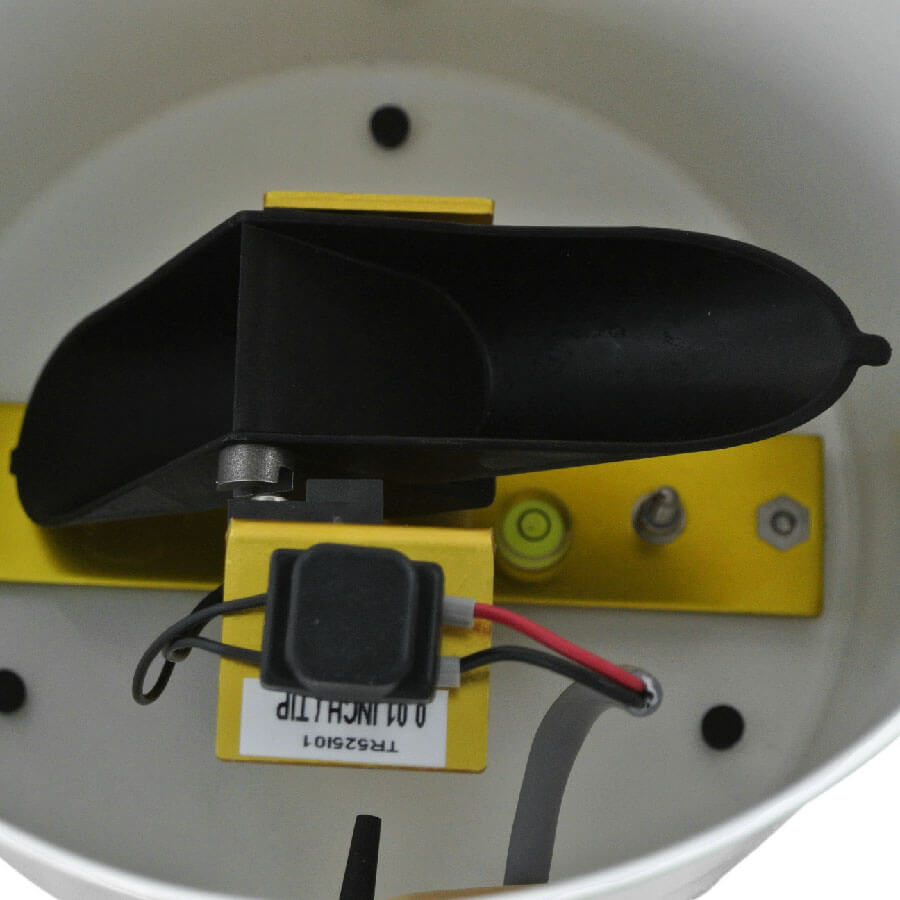

Tipping Bucket

Injection molded black polypropylene promotes water shedding.

Polished stainless steel shaft is suspended in machined brass pivots.

Cable

Dyacon uses an outdoor-rated cable with PVC jacket.

Data Connection

Each bucket tip momentarily closes a reed switch, indicating one incremental step of the gauge resolution.

Mounting

RGTB-525’s includes an integrated bubble level and a Dyacon-designed, tilt-and-pivot mounting system with both clamp and lock screws for a rigid and redundant adjustment system. The design allows for placement on any pipe, post, as well as flat surfaces.

Specifications

| MEASUREMENT | |

|---|---|

| Orifice/Collector | 6.06 inch (15.4 mm) 200 mm |

| Resolution | One tip per 0.01” |

| Accuracy | 1% at 0 to 2 inches/hr (o-50 mm/hr) |

| Resolution Options | 0.2 mm and 0.01” (standard) |

| ENVIRONMENTAL | |

|---|---|

| Operating Humidity | 0% to 100% RH |

| Operating Temperature | 0°C to 70°C |

| Storage Temperature | -40°C to 70°C |

| ELECTRICAL | |

|---|---|

| Switch Characteristics | 135 ms switch closure 0.75 ms debounce time 2 A max @ 30 VDC |

| Wire Connection | 2-position screw terminal strip |

| Cable | 10 feet (3 m) 2-conductor, 20 AWG, PVC Jacket, Xtraguard outdoor cable |

| MECHANICAL | |

|---|---|

| Body | Injection-molded ABS or Polypropylene |

| Mounting System | Anodized aluminum Stainless steel band-clamp and screws 3x 0.2 inch (5.1 mm) screw holes |

| Orifice Debris Screen | Perforated and anodized aluminum with retaining clip. |

| Tipping Pivots | Brass |

| Weight | 525i - 2.4 lbs (1.1 kg) 4 lbs ship weight |

| Dimensions | As Shipped, including mounting system: 525i - 12 x 7.5 x 7 inches (30 x 19 x 18 cm) |

| ACCESSORIES | |

|---|---|

| Accessories | Bird spikes are available. |