Tech Fascination

When a new technology comes out, it tends to get over-used. Often it is used where it makes a splash, but is impractical.

Blue LEDs for example. The light is a high-energy wavelength. When used on visual displays, such as in your car instrument panel, they can appear brighter than a red or yellow. Consequently, it may be difficult to tell whether the button your are pressing is defrost or A/C. And, speaking of cars, who likes the bright, blue HID head lights??

UAVs are another case in point. As a single-function toy, the shine often wears off before they crash. But, for an industrial user, UAVs can play a valuable role. The practical applications are still unfolding.

Ultrasonic Anemometers

The allure of new technology can be practical as well as trendy. Ultrasonic anemometers offer the potential to resolve vulnerabilities of mechanical anemometers; marketing information often promotes the lack of moving parts.

The notion of a static instrument determining wind speed and direction is rather intriguing. But in a professional environment, fascination for the latest tech must also be tempered with practicality.

Ultrasonic wind sensors are now available across the price spectrum, from a few hundred dollars to several thousand. Like most things, you get what you pay for. Measuring the time-to-travel of a sound pulse is really rather rudimentary; electronics do timing very well. Most products work well on the bench or in “typical” conditions. It is reliability over the board range of conditions that exposes the weak from the strong, the good from the bad, and (generally) the cheap from the expensive.

In addition to the advantage of no moving parts, ultrasonic anemometers can be very compact. The small size can also make them easy to heat.

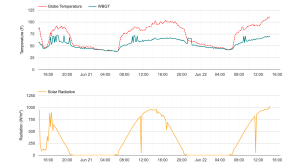

Since there is no mechanical inertia, ultrasonic anemometers can measure very low wind speeds. But, this does not mean that wind measurements are instantaneous, nor accurate. Conventional ultrasonics can experience spurious measurements at low wind speeds.

Due to the turbulent nature of air, sonic anemometers must take multiple measurements in order to provide a wind speed value. Multiple measurements are also necessary to eliminating noise, spurious measurements, and effects of transducer contamination. The number of sound pulses and numerical processing of these measurements will affect the final value produced.

In some sensors, the number of samples used for measurements is configurable. A 1 Hz rate (once per second) sample frequency is typical. Depending on the sampling and filtering, the resulting value may act similar to mechanical momentum.

Snow, rime, and rain are vulnerabilities of all wind measurement devices. For unheated sensors, the vulnerability isn’t much different and will be affected more by the mechanical design than the measurement technology.

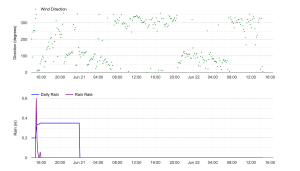

Ultrasonic transducers are affected by rain. That is why most designs have the transducers mounted on a top “hat,” facing downward. Nevertheless, splashing of wind-blown rain inside of the measurement cavity may cause some disruption of the transducer and measurements.

Insects often like dark, protected spaces. Spiders like to suspend their webs between structural gaps. Depending on the insect environment, ultrasonic sensors can create inviting compartments. Bird contamination can also disrupt ultrasonics. The meteorological department of my state department of transportation abandoned ultrasonic anemometers for their highway monitoring due to these vulnerabilities.

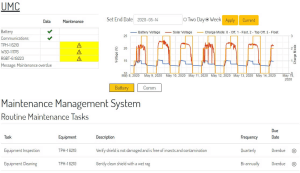

While the technology itself may be “maintenance-free,” it does not mean that the equipment does not need to be serviced.

Finally, ultrasonic anemometers are typically expensive.

3-Cup Anemometer

In selecting the right tool for the job, “old” technology shouldn’t be eliminated from consideration.

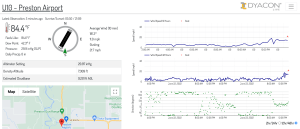

While many ultrasonic anemometers claim to be “low-power,” they are no where close to mechanical anemometers. For example Dyacon WSD-1 with digital output only draws about 2 mA. As a comparison, I am not aware of a sonic that is lower than 17 mA. Most that I have seen are in the 30 mA to 60 mA range.

In the power budget, one also has to consider the device that is reading the sensor. So, the anemometer is only part of the equation.

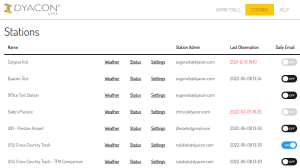

A fully operational Dyacon weather station with cell phone draws less than 30 mA average.

Why is power usage important? Because it impacts the cost of the full system and ongoing maintenance. More power means, larger battery, larger enclosure, larger solar panel, larger brackets, larger shipping boxes, higher shipping cost, and higher maintenance cost.

Birds and bugs typically have no effect on Dyacon wind sensors. A bird may perch on the top for a while, but, due to its slender design, it typically can’t be fouled by what they leave behind. The moving components and small gaps are not susceptible to insect fouling.

Ah, but, what about the wear components?

Unlike most wind vanes, Dyacon uses a magnetic sensor. The anemometer itself uses a reed switch. Both are non-contact elements. Yes, the bearings can become contaminated. A service interval of 3 to 5 years is recommended, depending on the environment. Until that time, all you have to do is visually ensure that the components are moving. This makes for intuitive troubleshooting.

Dyacon wind sensors are mechanically robust. Our sensors have survived a number of falls and bird impact. The cups are replaceable in the field. The aluminum mechanism ensures reparability, protecting the user’s investment.

Summary

Two main points:

- Select the right tool for the job. Both of the above technologies have their place.

- The wind sensor is only one piece of the system.

We strive to provide professional equipment for the commercial and industrial environment. Not only is our equipment robust, with good connectivity options, it is generally easy to use. This allows users to install, configure, and maintain the equipment, minimizing both down time and total cost of ownership.

Please drop us a note.

Eugene

Since it can be deployed in a matter of seconds and does not require extra tools or equipment to set up (except possibly a hammer to implement ground stakes), the quick-deployment tripod is a practical solution for short-term, provisional implementation. QDT-1 is equipped with adjustable leg extensions to facilitate deployment on uneven surfaces, up to a 12% slope.

Since it can be deployed in a matter of seconds and does not require extra tools or equipment to set up (except possibly a hammer to implement ground stakes), the quick-deployment tripod is a practical solution for short-term, provisional implementation. QDT-1 is equipped with adjustable leg extensions to facilitate deployment on uneven surfaces, up to a 12% slope.

Every weather station company has their own stories about equipment caught in wildfires, to which we add our own.

Every weather station company has their own stories about equipment caught in wildfires, to which we add our own.